Individual design engineering assistance with DELTA CALC®

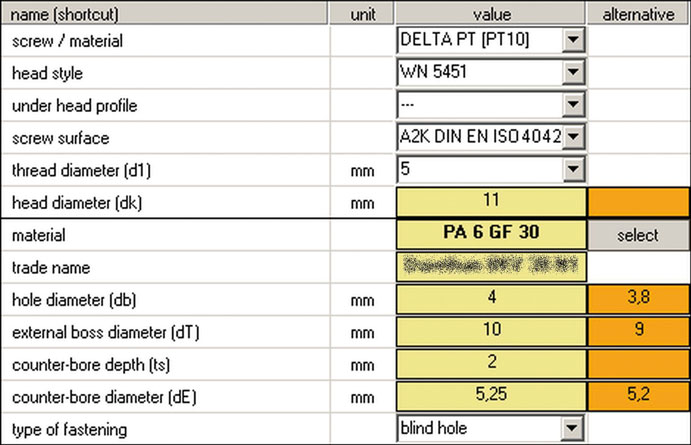

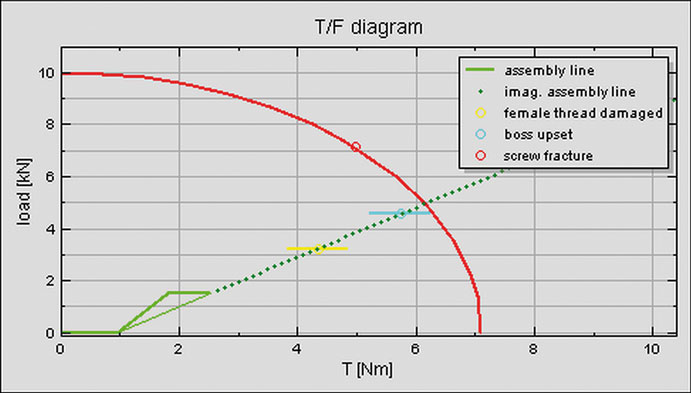

As valuable support for design engineers and developers EJOT offers a prognosis program for the pre-dimensioning of direct fastening into thermoplastics. In dependence on material and pilot hole dimension, the fastening parameters of the DELTA PT® screw can be calculated with this tool. Significant savings effects are possible in particular during the design stage of a component.

The EJOT DELTA PT® screw is the high-capacity fastening element for reliable and trouble-free direct fastening into thermoplastic (see image I). A research program, based on the mechanical parameters of many thousands of applications and test assemblies, has proven that reliable clamp load calculations are also possible for thermoplastic material (compare to VDI 2230). On this basis, the DELTA PT® geometry and the corresponding prognosis program EJOT DELTA CALC® have been developed.

Based on the VDI 2230 many effective calculation programs are available today, but their application range is limited to the calculation of metric screw joints in metallic materials. For the calculation of self-tapping joints in plastics, the guidelines of the VDI 2230 are not completely applicable. In particular the process of thread-forming and the specific material properties of thermoplastic material have not been considered. With the development of the DELTA CALC® prognosis program the industry leader EJOT has addressed this problem in order to offer an optimum design aid to the customer. The result is an effective and precise calculation tool, which has already been proven in many applications and is also subject to ongoing optimisation and further development.

Brief characteristics of the possible applications of the EJOT DELTA CALC® prognosis program:

This calculation program is now also available to the customer online under www.ejot.com, in addition to other services such as download of CAD data and product information. After the required registration under "CAD & more", design engineers and developers can use the so-called "light version" of DELTA CALC® directly online. "Light", because the tool has been developed for highest possible user-friendliness, so the customer can use it online and independently. For highly complex applications, that might not be covered by the light version, the customer can access the complete fastening technology know-how of the EJOT application engineers and of the APPLITEC laboratory.